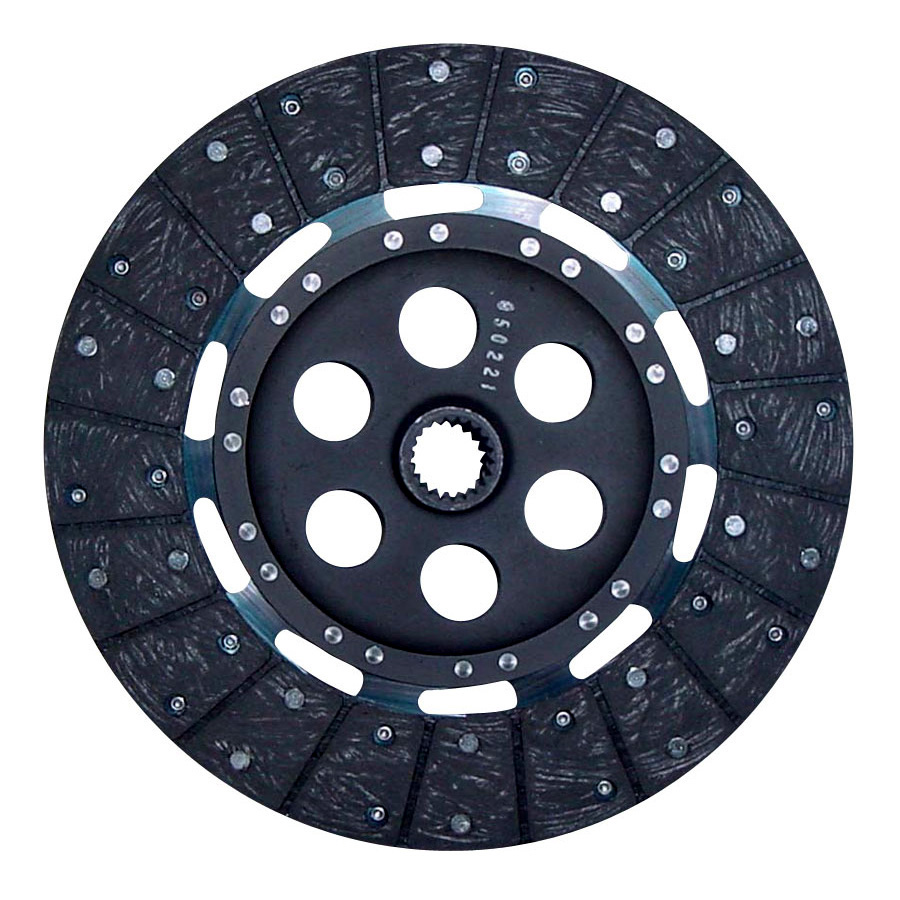

clutch disc material – clutch material sheet

The clutch disc ensures a smooth transition during every engagement, while also standing up to the abuse of this action, If the clutch disc is going to last, it must be covered with a friction material that: 1 Can withstand the torque and RPM of the engine , 2 Can withstand the …

Explorez davantage

| What is the Best Clutch Material for Friction? | kor-pak,com |

| Automatic Transmission Friction Clutch Plate Supplier | www,raybestospowertrain,com |

| Which Clutch Disc is Better : Full Face or Puck Style | speedeclutch,com |

| Miba: Friction materials | www,miba,com |

Recommandé pour vous en fonction de ce qui est populaire • Avis

What is the Best Clutch Material for Friction?

Replacement friction and steel clutch discs for: Twin Disc; Dana / Formsprag / T,B, Woods; Rockford; Carlyle Johnson and more; Applications include: Mechanical Threading Clutches; Spindle Stopping Clutches ; Mechanical High Speed and Feed Clutches; Logan Groove Pattern Descriptions and Friction Materials Logan Groove Patterns, Logan groove patterns enable oil to be redirected for fast heat

Friction Material

Friction Discs

Industrial Friction Materials clutch relining services will reline any kind, size or type of clutch from a small centrifugal sewing machine clutch to a large 14” tractor disc clutch plate, There are many other types of clutch we refurbish such as paddle & cone clutches etc, The refurbishment service includes the removal of the old linings, thorough cleaning & surface preparation, the fitting

Friction and Steel Clutch Discs

· In short choosing the correct clutch disc material for your car’s upgrade is significantly important as is how that specific material is put into action via full-face discs versus the various puck-style disc configurations Selecting the proper clutch for your car of course then breaks down into how you intended to use your car, Is it comfortable as a daily commuter, or do you take it to

What is the material used for making clutch plates?

Clutch materials

Clutches

There’s the clutch “plate” and pressure plate assembly – which is usually made from steel – and then there’s the clutch disc, which is usually steel with a friction material applied, I’m guessing this question is regarding the different types of f

Choose from our selection of friction material, including high-friction brake and clutch lining, metal-free brake and clutch lining, and more, In stock and ready to ship,

Clutches Explained: ACT McLeod Racing and SPEC Weigh In

Disc Brake Linings, Offered by Clutch Engineering, these Bremskerl disc brake linings are made of high-quality materials, When manufactured into disc brake linings, these materials help evenly distribute energy across the entire disc surface, This helps reduce wear, increasing both linings and rotor life, Bremskerl provides air disc brake pads and drum brake linings for bus, trailer, truck and

· This vital clutch disc makes sure that this engagement and disengagement of the flywheel happens smoothly every time Early clutches were made with weak clutch discs that would wear out after just a minimal amount of usage But today we have clutch material that can withstand high friction high heat and the force of the pressure plate In this article we’ll run you through the best

Temps de Lecture Estimé: 3 mins

The clutch disc is generally made from grey cast iron FG 300Because of its high heat and wear resistant but its ramic based composites are used as clutch disc material due to its high thermal conductivity and diffusivity The material is considered valuable for to dissipate heat at higher rate st-42IS 1079 is used as clutch plate material because of its wear resistance property but its

· Semi-metallic clutch materials look similar in construction to a regular organic clutch material but can withstand much higher levels of heat and are thus more suitable for high-torque applications, The clutches can still feature a woven structure, but instead of organic materials they will contain stands of brass or copper to improve the burst strength of the material while also increasing

clutch disc material

Industrial Clutch Parts Ltd, manufactures an extensive range of friction discs suitable for various clutch and brake requirements, These discs are available in a variety of different dimensions, friction combinations, and provide the tightest of tooth tolerances on the market, Available in organic, woven kevlar and sintered materials,

Friction Material

· Clutch materials 1, 1, Organic disc material Organic friction material is made of cellulose, usually reinforced with some heat resistant stuff like chopped fiberglass and mineral wool in a thermosetting phenolic resin base, The cellulose is like cardboard and helps initial grip, The mineral wool and fiberglass strands provide burst strength, which is the friction material’s resistance to

Review on Different Materials Utilized in Clutch Plate

· Fichier PDF

Clutch Friction Materials Explained

Clutch materials

Friction Materials

This material was initially designed for heavy haulage and industrial applications in mind, however we have now put this material to good use in our bespoke built clutch kits and now more than ever, the Land Rover applications which require a material that can handle the extra torque and heat generated whilst off road, This material offers high mechanical strength, higher strength of anti