hybrid solid oxide electrolyzer cell – commercial solid oxide fuel cell

– Solid oxide electrolyzer SOEC $1,000/kW not available – Deep water storage, $15/kWh not available today* – Oxy-combustion CC $720/kW not available today – LCOE hybrid = 32¢/kWh * Additional storage cost of O2 increases cost from $10 kWh to $15 per kWh,

Solid Oxide Electrolyzer Cell Modeling: A Review

· Fichier PDF

Solid Oxide Fuel/Electrolyzer Cells

The SOEC UNIT uses mPower‘s Solid Oxide Electrolysis Cells SOEC technology, the most energy efficient electrolysis technology, The SOEC cells operate at high temperatures between 750 and 850 °C and ambient pressure, The thermoneutral operation of the SOEC UNIT eliminates the high cooling requirements typical for PEM Polymer Exchange Membrane and alkaline technologies,

Solid oxide fuel cells SOFC use a solid oxide material as the electrolyte and are predominantly used for generating electricity typically through the electrochemical oxidation of H2 via oxygen ions conducted to the anode side, SOFCs are modular, scalable, efficient, and use a variety of hydrocarbons as fuel and tolerate some degree of common fossil fuel impurities, such as ammonia and chlorides,

Hybrid Hydrogen Energy Storage

· Fichier PDF

· A joint research team, affiliated with UNIST has introduced the Hybrid-Solid Electrolysis Cell Hybrid-SOEC system with highest reported electrochemical performance in hydrogen production, The proposed system has attracted much attention as a new promising option for the cost-effective and highly-efficient hydrogen production, as it shows excellent performance compared with other water-electrolysis …

DOE Invests $34 Million to Develop Small-Scale Solid Oxide

Solid oxide electrolyzer cell

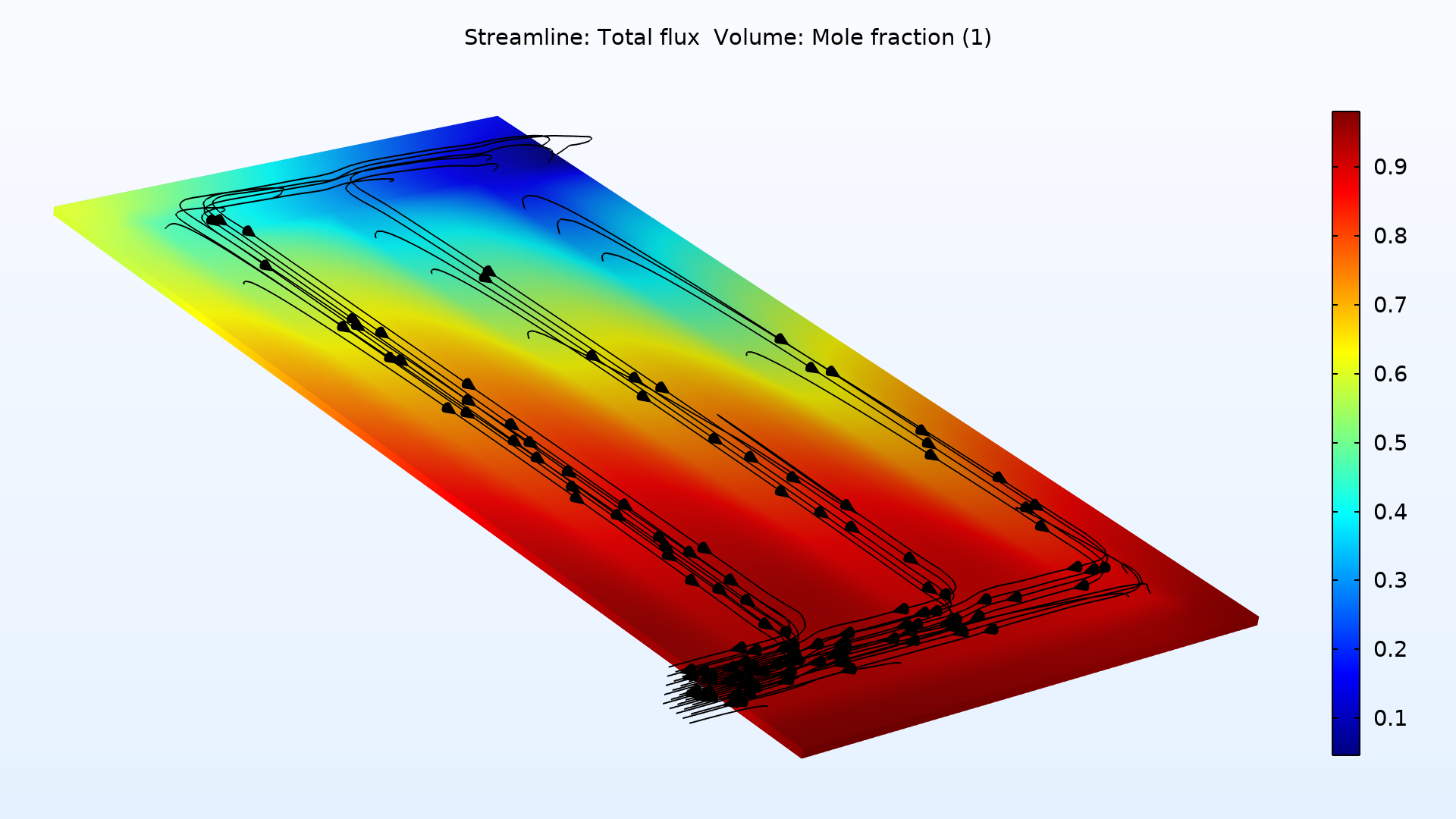

Solid Oxide Electrolyzer Cell SOEC is a very good candidate technology for securing sustainable develop-ment for the future It allows CO 2 to be recycled into usable fuels and has potential for hydrogen economy, In this work the authors focus on development of SOEC through modeling di erent aspects of the cell: from

The Future is Here for Solid Oxide Electrolysis Cell

· In this study we present the novel concept of “Hybrid solid oxide electrolysis cell Hybrid-SOEC” based on mixed ionic conducting electrolyte BZCYYb allowing simultaneous the oxygen-SOEC and proton-SOEC operation The excellent stability is achieved under the Hybrid-SOEC operation without observable degradation for 60 h Furthermore in the Hybrid-SOEC system, the highest electrochemical performance for …

Cited by : 89

PDF Hybrid-solid oxide electrolysis cell: A new strategy

Hybrid-solid oxide electrolysis cell: A new strategy for

A solid oxide electrolyzer cell is a solid oxide fuel cell that runs in regenerative mode to achieve the electrolysis of water by using a solid oxide, or ceramic, electrolyte to produce hydrogen gas and oxygen, The production of pure hydrogen is compelling because it is a clean fuel that can be stored easily, thus making it a potential alternative to batteries, Electrolysis is currently the most promising method of hydrogen production from …

Stability test of single cell as a Hybrid-SOEC a Time-dependence of the cell voltage applied 045 A cm −2 at 550 °C during Hybrid-electrolysis under 90% H 2 and 10% steam fed in the hydrogen

Temps de Lecture Estimé: 7 mins

Hybrid-solid oxide electrolysis cell: A new strategy for

Moreover the Hybrid SOEC exhibits no observable degradation in performance for more than 60 Her research interest includes on solid oxide fuel cells and solid-oxide electrolysis cells with efficient and stable electrode materials including layered perovskites and proton-conducting oxides In particular, she currently focuses on the development of multilayer ceramic capacitors for

Cited by : 89

Multi-objective optimization and comparative performance

Solid Oxide Electrolyser Cell

· This FOA seeks to develop advanced technologies that can progress the present state of small-scale solid oxide fuel cells SOFC hybrid systems using solid oxide electrolyzer cell technologies to a point of commercial readiness for hydrogen production and power generation It also seeks validation of SOFC using syngas from gasification facilities,

hybrid solid oxide electrolyzer cell

Solid Oxide Electrolysis Cells — Operation at high temperature 0 50 100 150 200 250 300 0 100 200 300 400 500 600 700 800 900 1000 Temperature ºC 0,00 0,26 0,52 0,78 1,04 1,30 1,55 Volt CO 2 o CO + ½O 2 Total energy demand H f G f T S f 0 50 100 150 200 250 300 0 100 200 300 400 500 600 700 800 900 1000 Temperature ºC 0,00 0,26 0,52 0,78 1,04 1,30 1,55 Liquid Gas Volt H 2 O o

· In this paper a hybrid biomass-based solid oxide fuel cell/solid oxide electrolyzer cell/gas turbine is proposed considering Air O 2-Enriched air O 2 and pure CO 2 as the gasification agents The proposed system is then comprehensively studied and compared from energy exergy exergoeconomic and environmental impact standpoints through the parametric study, considering different gasification agents, The exhaust gases of the solid oxide fuel cell is recovered in a gas turbine …

Hybrid-Solid Electrolysis Cell System

Solid Oxide Electrolysis Cells

· Fichier PDF

· SOECs make use of two compounds whose relative scarcity leads to high unit prices: zirconia based on the element zirconium and yttria based on the element yttrium, They conclude that “solid oxide cells providing 1 TW of power in fuel cell mode would require just 1 month’s worth of global ZrO2 production and 21 months’ worth of Y2O3, To put these numbers into perspective: 24 hours of 1 TW of power generated using …